Depending on the work being performed, a glove’s level of cut resistance may determine whether a workplace injury is minor or severe.

Standards in Cut Resistance

For product consistency, the American National Standards Institute (ANSI) set standards for cut resistance in safety gloves. This helps ensure consistent cut resistance ratings regardless of glove manufacturer, cost, style, materials, and design.

This is good news for glove users because the new standards better equip safety managers to find the appropriate protection for the job.

To help you make the best choices when selecting gloves for cut resistance, we’ve answered four of the most frequent questions about cut resistance.

1. WHAT IS A CUT SCORE?

A cut resistance score is measured by how many grams of pressure can be applied by a razor blade moving in a straight path across a swatch of glove fabric before cutting the glove. The “gram score” tells you how many grams of pressure the glove withstood before cutting through 0.8” (20 mm) or more. It is the average of multiple runs, using a new blade on each pass, and this “gram score” determines the Cut Score.

2. WHAT HAS CHANGED ABOUT CUT SCORES?

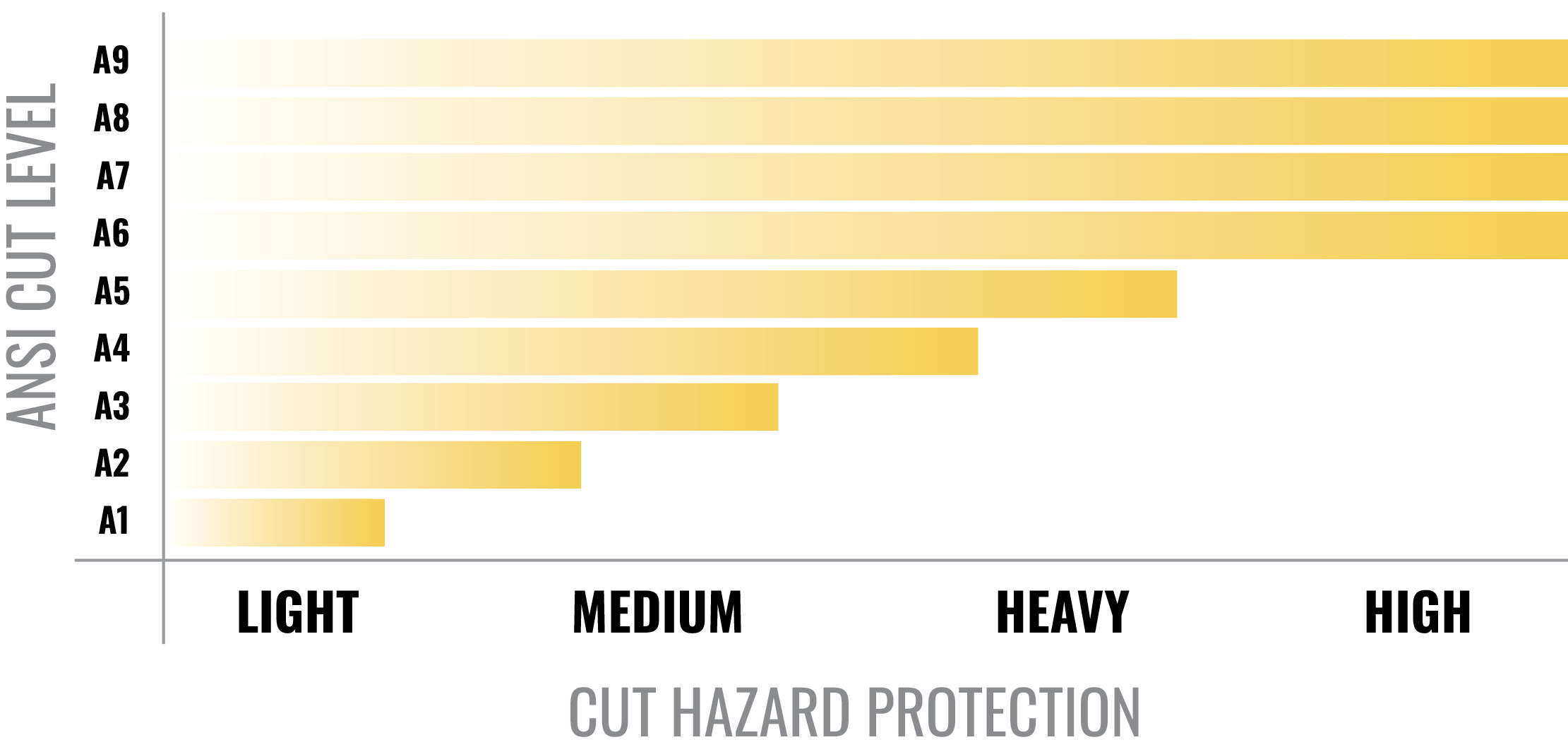

In the past, the ANSI rated gloves on a scale from 1 to 5. However, in February 2016, the ISEA released a new ANSI 105 hand protection standard to reflect innovation and advances in material technologies. The new standard includes updates to the classification levels for cut resistance (Cut Score) with a scale of 1 to 9. It also updates the method of testing gloves for cut resistance.

3. WHAT ARE THE CURRENT TESTING STANDARDS?

The current standard uses a Tomodynamometer Test Machine (TDM) to measure the weight in grams required for a blade to cut material. This improves accuracy of test results by designating a uniform test method using a single testing machine. All tests now require using the ASTM F2992-15 method on the TDM-100 machine.

4. HOW ARE CUT-RESISTANT SCORES CLASSIFIED?

The classification for cut resistance helps identify the appropriate protection for a job, because it precisely defines levels of cut resistance with narrowly gradated levels while providing for expanded upper limits on cut resistance.