Why It Matters

- Noise-Induced Hearing Loss (NIHL) is entirely preventable.

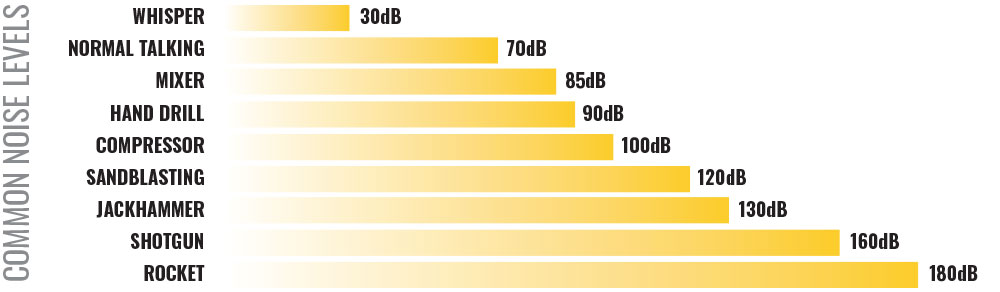

Constant or impulsive noise can permanently damage hearing. - Focus & health:

Proper protection reduces fatigue, stress, and distraction, improving productivity. - Compliance:

OSHA requires employers to implement a Hearing Conservation Program when noise exposure reaches an average of 85 dBA over an 8-hour work shift (TWA). According to OSHA, this program includes monitoring noise levels, providing hearing protection, offering annual hearing tests, and training employees on the risks and prevention of hearing loss.

Types of Hearing Protection

More isn’t always better. If protection is too strong, workers may miss alarms or verbal cues. Choose adequate attenuation for the actual noise and confirm with fit-testing or quick checks.

Choosing the Right Hearing Protection

Noise Reduction Rating (NRR): The NRR measures how much noise a hearing protection device can block under laboratory conditions. Ratings typically range from 22–33 dB for earplugs and 20–31 dB for earmuffs, with higher numbers indicating greater potential attenuation.

- Earplugs (foam, reusable, custom-molded): Common in high-noise environments; foam plugs often provide the highest NRR (up to 33 dB).

- Earmuffs: Easier to fit consistently and preferred in intermittent noise or environments requiring quick removal

- Electronic earmuffs/earplugs: Allow speech and environmental sounds while filtering harmful peaks—widely used in manufacturing, airports, and shooting ranges.

Comfort: Offer options (sizes, materials) so workers can wear protection for full shifts.

Environment: Construction, manufacturing, warehouses, airports, etc. may need different styles (earplugs vs. earmuffs, or both for extreme peaks).

Attenuation Targeting (and when to use dual protection)

Picking “the strongest plug” can backfire. Aim to bring the protected exposure to ~70–80 dBA at the ear so workers can still hear warnings and communicate.

How to target the right protection:

- Start with area noise: LAeq/TWA (or the best available reading).

- Pick a product’s labeled NRR as a starting point.

- Use a conservative field estimate: Real-world ≈ NRR × 0.5 (rule of thumb).

- Protected-at-ear ≈ Area noise − (NRR × 0.5).

- Goal: end up around 70–80 dBA. If you’re still >80 dBA, consider dual protection (plugs + muffs).

EXAMPLE:

- Area noise = 98 dBA

- Foam plug NRR 33 → field estimate ≈ 16–17 dB

- Protected-at-ear ≈ 98 − 16 = 82 dBA → Close. Improve insertion/fit or move to higher-performing plug style; if tasks run hot or peaks occur, add muffs.

Rule-of-thumb:

Area noise (LAeq)

Target solution

Notes

85–92 dBA

Reusable or foam plugs (NRR 25–33)

Comfort & consistency matter more than max NRR.

93–99 dBA

High-NRR foam plugs (≈33) or quality earmuffs (NRR 27–31)

Choose based on task, compatibility, and user preference.

100–105 dBA

High-NRR plugs or muffs; verify with fit

If communications are critical, consider electronic muffs with limiters.

>105 dBA or impulse peaks

Dual protection (plugs + muffs)

Train on correct sequencing; verify seal with eyewear/helmets.

Fit-check & Verification:

- Teach the roll-pull-hold for foam plugs.

- Do quick checks: balanced muffling in both ears; no visible plug sticking out.

- For programs with higher risk, add fit testing (e.g., Personal Attenuation Rating, PAR) to prove the chosen device + fit actually achieves the target.

1. Clean Your Hands:

Ensure your hands are clean to avoid introducing any dirt or contaminants into your ear canal.

2. Roll the Earplug:

Take an earplug and roll it into a thin, cylinder-like shape using your fingers. This makes it easier to insert.

3. Pull Your Ear:

With your opposite hand, reach over your head and pull your ear gently upwards. This straightens the ear canal, making it easier to insert the earplug.

4. Insert the Earplug:

Gently insert the rolled earplug into your ear. It should fit snugly without any discomfort.

5. Wait for Expansion:

Once inside, the earplug will expand to fill the ear canal and create a secure seal. This might take a few seconds to a minute.

6. Check the Fit:

To check the fit, you can try speaking or having someone speak to you. Voices should sound muffled if the earplug is fitted correctly.

Avoiding Over-protection

More isn’t always better. If protection is too strong, workers may miss alarms or verbal cues. Choose adequate attenuation for the actual noise and confirm with fit-testing or quick checks.

Compatibility with Other PPE

- Eyewear: Thick temples can lift earmuff cushions and reduce attenuation (several dB). Slim temples help preserve the seal.

- Hard hats/hoods: Use cap-mounted muffs on helmets; neckband muffs with hoods/respirators.

- Respirators: Most styles work with earplugs; verify there’s no interference with muffs.

Special Requirements

- Food & beverage: Use detectable, high-visibility earplugs or corded options to prevent loss/contamination.

- Electrical/utility/mining: Choose dielectric (non-metal) earmuffs and non-conductive plugs.

- Communication needs: Electronic “hear-through” muffs/in-ear systems amplify important signals while limiting harmful noise; Bluetooth/radio options are available.

Make Protection Easy to Grab (and Reduce Waste)

Touch-free wall dispensers keep NRR 33 earplugs at arm’s reach and help control use and hygiene. Place them at entry points, near high-noise areas, and in break spaces to encourage consistent wear with less waste.

Your Organization’s Hearing Conservation Program Should Include:

Noise Monitoring – If employees are exposed to noise over 85dB for an 8-hour time-weighted average (TWA), employers are required to institute a hearing conservation program that includes:

Engineering Controls – Develop a written program

Testing – Provide diagnostic hearing testing – both baseline and annually

Protective Equipment – Provide hearing protection equipment

Training – Provide training to ensure workers know how to use the equipment

Need help matching protection to your noise?

Arbill’s team can review your areas/tasks, recommend options, and provide trainings so your people get the intended protection.

I WANT TO LEARN MORE ABOUT ARBILL’S COMPREHENSIVE APPROACH TO SAFETY!

*All fields are required.